Difference between revisions of "Lathe"

(→How to use) |

m (→Lathe controls) |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''(Jet WMH Tool Group) BD-8 Metal Lathe Diameter 20/450 mm''' | '''(Jet WMH Tool Group) BD-8 Metal Lathe Diameter 20/450 mm''' | ||

| − | Airlab Lambrate. | + | [http://www.waltermeier.com/eu/fertigung/en/jet_machinery/metalworking/turning.html Producer website] [http://www.waltermeier.com/icms/media/download.html?media.id=5499 Data sheet] |

| + | (Located at Airlab Lambrate). | ||

[[Image:Tornio.jpg]] | [[Image:Tornio.jpg]] | ||

| Line 12: | Line 13: | ||

[[Image:Control_panel.jpg]] | [[Image:Control_panel.jpg]] | ||

| − | Switch | + | Switch the square button on the bottom part of the control panel to power on/off the lathe. |

| − | + | The red Rounded botton sorrounded by a yellow circle is used for Emergency STOP. If something is going wrong press it quicly to stop the lathe. Rotate to unblok the lathe. | |

| + | |||

6 Oval buttons under the display are used for: | 6 Oval buttons under the display are used for: | ||

* I(green): start the movement | * I(green): start the movement | ||

| Line 28: | Line 30: | ||

A typical way to use the late is characterized by the following steps: | A typical way to use the late is characterized by the following steps: | ||

| − | * | + | * place the piece to work in the rotating part of the lathe |

| − | * Move longitudinally close to the piece | + | * choos the tool to use according to the type of work to perform |

| − | * | + | * Move longitudinally the tool close to the piece |

| + | * Do a first fine work to make the zero. This operation means to perform a first work of the piece going in and then out in order to remove a little part of material. When the tool is out of the piece, reset measuring instruments to keep track of the zero reference position. | ||

| + | * Do the work: Move the control to the desired step (i.e 2mm) and do the work. | ||

| + | |||

| + | Remember that only to types of lavoration can be performed, according to the possible movements of the tool: longitudinal and orizzontal. | ||

| + | |||

| + | '''Example 1'''. Reduce the diameter. Move longitudinally close to the piece. Make the zero ad adjust the step by controlling the orizzontal movement. Do the work by moving longitudinally. | ||

| + | |||

| + | '''Example 2'''. Make the frontal surface. Move longitudinally close to the piece. Make the zero ad adjust the step by controlling the longitudinal movement. Do the work by moving orizzontally. | ||

| + | |||

| + | |||

| + | Remember that for a manual movement use both hands to rotate slowly the control. For an automatic movement remember to adjust correctly the control, since the same lever is used to switch between the automatic longitudinal or orizzontal movement. | ||

| − | + | Note that the speed of automatic movements depens on the gears that are currently mounted on the lathe. In order to change the speed you have to change the gears (.. a long long operation :D) | |

If the tool is goog enough only small pieces of materia are cutted away. Long pieces of material means that we are not using a good tool, it can broke suddenly. Stop the work and prepare the tool with a specific machine(TODO) | If the tool is goog enough only small pieces of materia are cutted away. Long pieces of material means that we are not using a good tool, it can broke suddenly. Stop the work and prepare the tool with a specific machine(TODO) | ||

Latest revision as of 17:36, 3 February 2010

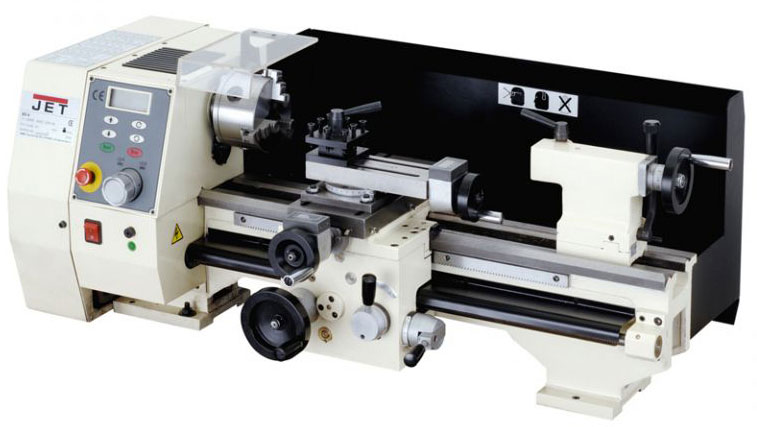

(Jet WMH Tool Group) BD-8 Metal Lathe Diameter 20/450 mm

Producer website Data sheet

(Located at Airlab Lambrate).

How to use

This is a short manual that describes how to use this tool. The manual came out from the course held in 2009. Note that only the people that have followed that course are allowed to use such machine!

Power on/off

If you are allowed to use the lathe use you personal key to switch on the general supply.

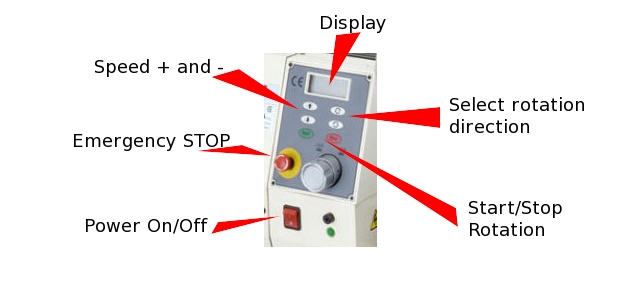

Switch the square button on the bottom part of the control panel to power on/off the lathe. The red Rounded botton sorrounded by a yellow circle is used for Emergency STOP. If something is going wrong press it quicly to stop the lathe. Rotate to unblok the lathe.

6 Oval buttons under the display are used for:

- I(green): start the movement

- O(red): stop the movement

- Up arrow / Down arrow: Invert the rotation movement

- + / - : Adjust the rotation speed. The speed depends on the material to work and to the type of lavoration: 300g/m for a rough lavoration, 600 g/m for a fine lavoration. 300g/m is good for Iron, Alluminium. For plastic, very slow rotation with high longitudinal velocity.

Refrigerant liquid is used only for strong material like stell. Do not use on alluminium

There exists a control to disconnect the part which keep the piece from the motor but it unuseful.

Lathe controls

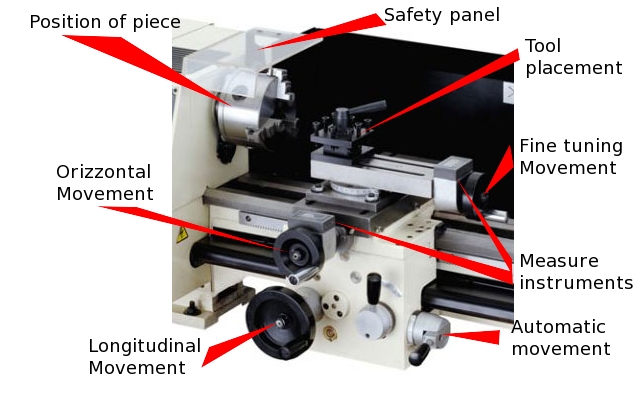

A typical way to use the late is characterized by the following steps:

- place the piece to work in the rotating part of the lathe

- choos the tool to use according to the type of work to perform

- Move longitudinally the tool close to the piece

- Do a first fine work to make the zero. This operation means to perform a first work of the piece going in and then out in order to remove a little part of material. When the tool is out of the piece, reset measuring instruments to keep track of the zero reference position.

- Do the work: Move the control to the desired step (i.e 2mm) and do the work.

Remember that only to types of lavoration can be performed, according to the possible movements of the tool: longitudinal and orizzontal.

Example 1. Reduce the diameter. Move longitudinally close to the piece. Make the zero ad adjust the step by controlling the orizzontal movement. Do the work by moving longitudinally.

Example 2. Make the frontal surface. Move longitudinally close to the piece. Make the zero ad adjust the step by controlling the longitudinal movement. Do the work by moving orizzontally.

Remember that for a manual movement use both hands to rotate slowly the control. For an automatic movement remember to adjust correctly the control, since the same lever is used to switch between the automatic longitudinal or orizzontal movement.

Note that the speed of automatic movements depens on the gears that are currently mounted on the lathe. In order to change the speed you have to change the gears (.. a long long operation :D)

If the tool is goog enough only small pieces of materia are cutted away. Long pieces of material means that we are not using a good tool, it can broke suddenly. Stop the work and prepare the tool with a specific machine(TODO)